HYDRANT, UNDERGROUND, PN16

Single shut off (K7)

Contact

AVK Industrial Nederland BV

Schorsweg 1 8171 ME Vaassen Netherlands

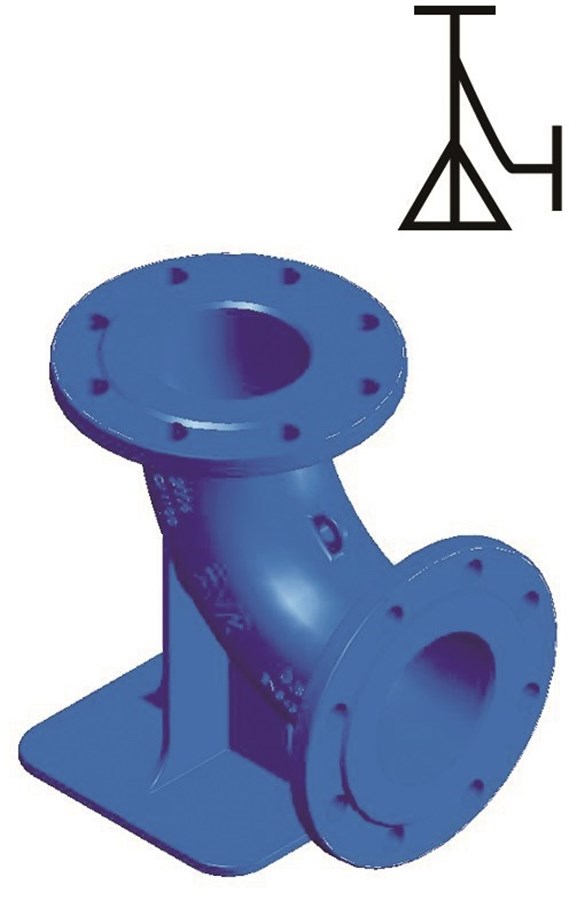

Underground fire hydrant to EN 14339 - Single shut off (K7) for drinking water and neutral liquids to max. 60° C

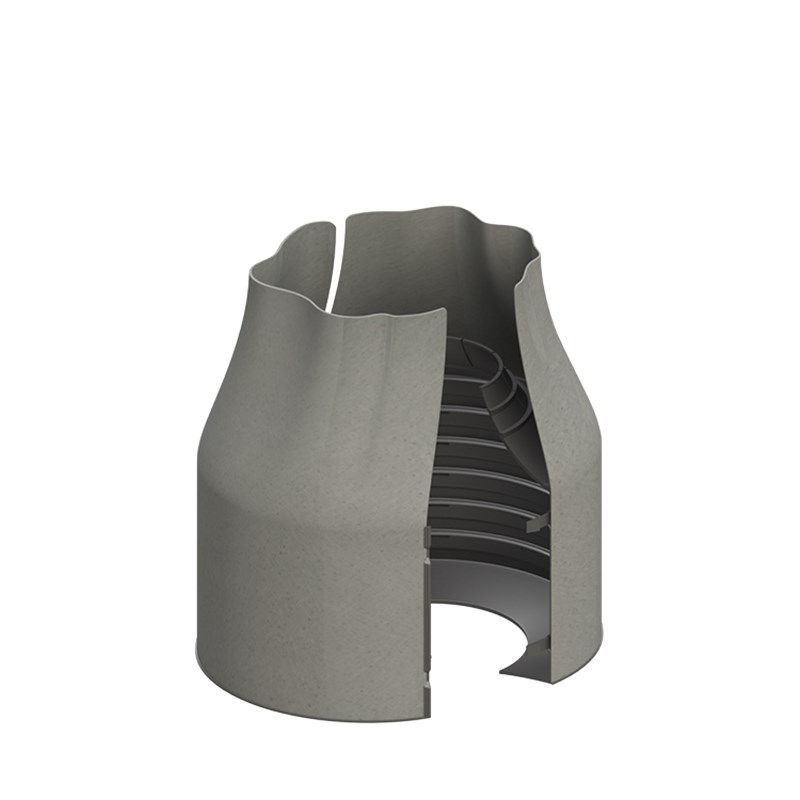

AVK S.35 underground hydrants are equal to high quality in every detail and meet or exceed the requirements of DIN/EN14339. The hydrants are available with either single shut-off or double shut-off system for a continued sealing of the hydrant during maintenance. The shutoff plug is vulcanized with PUR (Polyurethane) for maximum memory effect. The automatic drainage system secures total emptying of the hydrant after use.

| Variant 35/31-004 | |

|---|---|

| Connection: | Flanged |

| Material: | Ductile iron |

| DN: | DN80 - DN80 |

| PN: | PN 16 |

| Closing direction: | Clockwise to Close |

Features

- Frost-proof automatic drainage in flush proof design.

- Radial sealing valve seat of dezincification resistant brass.

- Disc with ductile iron core coated with PUR (Polyurethane) for maximum memory effect.

- Stem bearing with polyamide antifriction washer secures an easy and smooth operation.

- Blue epoxy coating to DIN 3476-1, GSK approved. Alternatively with inside and/or outside enamel to DIN EN ISO 11177.

- Kv value: 136 m3/h.

- Drainage: Residual flow: 11 ml. Time for drainage: 52 sec.

- Operating force resistance: MOT = 105 Nm, MST = 210 Nm.

Downloads

Datasheet

Certificate(s)

Reference nos. and dimensions:

Scroll for more info

| Reference no. | DN mm |

Pipe cover mm |

H3 mm |

Theoretical weight/kg |

Notes |

|---|---|---|---|---|---|

| 35-080-31-11015 | 80 | 750 | 471 | 21 | Lid with chain |

| 35-080-31-11020 | 80 | 750 | 471 | 21 | Bayonet coupling, self-closing cover |

| 35-080-31-21015 | 80 | 1000 | 721 | 25 | Lid with chain |

| 35-080-31-21020 | 80 | 1000 | 721 | 25 | Bayonet coupling, self-closing cover |

| 35-080-31-31015 | 80 | 1250 | 971 | 29 | Lid with chain |

| 35-080-31-31020 | 80 | 1250 | 971 | 29 | Bayonet coupling, self-closing cover |

| 35-080-31-41015 | 80 | 1500 | 1221 | 33 | Lid with chain |

| 35-080-31-41020 | 80 | 1500 | 1221 | 33 | Bayonet coupling, self-closing cover |

2D/3D drawings

Enquiry

Scroll for more info

Components

| 1. | Body | Ductile iron GJS-400-15 |

| 2. | Leaf membrane | EPDM rubber |

| 3. | O-ring | EPDM rubber |

| 4. | Bayonet | Ductile iron GJS-400-15 |

| 5. | Outlet cap | Cast iron GJL-250 (GG-25) |

| 6. | Chain w. ring | Steel, galvanized |

| 7. | Split pin | Stainless steel |

| 8. | Bolt | Stainless steel |

| 9. | Stem square cap | Ductile iron GJS-400-15 |

| 10. | Identifier disc | Plastic |

| 11. | Wiper ring | NBR rubber |

| 12. | O-ring | EPDM rubber |

| 13. | Bonnet | Ductile iron GJS-400-15 |

| 14. | O-ring | EPDM rubber |

| 15. | Washer | POM |

| 16. | Stem support | Ductile iron GJS-400-15 |

| 17. | Stem | Stainless steel 1.4021 |

| 18. | Stem nut | Brass |

| 19. | Operation pipe | Stainless steel |

| 20. | Drain pipe | Polyamide |

Test/Approvals

- Hydraulic test according to EN 1074-6

- Approved according to CE Reg. No. 0620-CPR-6122

- Approved according to DIN-DVGW Certificate NW-6401CL0291

Standards

- EN 1074-6, EN 14339:2005

- Flange drilling to EN1092, PN10/16